Did you know that by 2029, the global Digital Twin Technology market is projected to reach an impressive $125.7 billion? This staggering figure underscores the rapidly expanding influence of Digital Twin Technology across various sectors. The technology is no longer a futuristic concept; it's a present-day reality transforming industries through its ability to simulate, analyze, and optimize physical assets and processes in the digital realm.

Foundational Context: Market & Trends

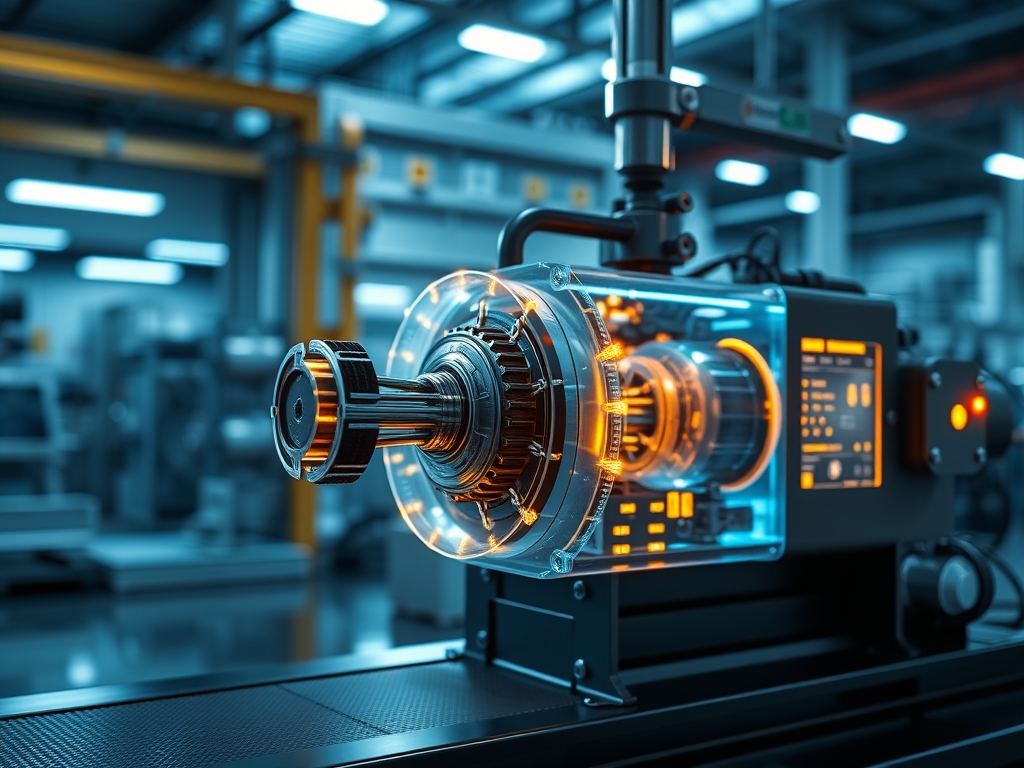

The Digital Twin market is experiencing exponential growth, fueled by the convergence of several key technological advancements. The Industrial IoT (IIoT) is a primary driver, providing the data streams necessary to feed and maintain digital twins. Simultaneously, cloud computing enables the storage and processing of vast data volumes, and AI/ML algorithms provide predictive capabilities. According to recent reports, the manufacturing and automotive industries are the largest adopters.

The trend points towards increasing sophistication in digital twin applications. Early implementations focused on simple asset visualization; now, we're seeing sophisticated simulations, real-time predictive maintenance, and optimized operational workflows.

Consider this comparison of digital twin adoption across key sectors:

| Sector | Market Share (Projected) | Key Applications |

|---|---|---|

| Manufacturing | 35% | Predictive maintenance, process optimization |

| Automotive | 20% | Design and testing, supply chain optimization |

| Aerospace | 15% | Flight simulation, maintenance planning |

| Healthcare | 10% | Patient monitoring, medical device simulation |

| Energy | 10% | Grid optimization, renewable energy management |

| Construction | 10% | Building design, construction process simulation |

Core Mechanisms & Driving Factors

The success of Digital Twin Technology hinges on several fundamental components:

- Data Acquisition: This involves collecting real-time data from sensors embedded in physical assets, machinery, and systems.

- Data Integration and Processing: The raw data needs to be integrated, cleaned, and transformed into a usable format. This often requires the use of sophisticated data management platforms.

- Modeling and Simulation: Building the digital replica requires advanced modeling techniques that capture the behavior and characteristics of the physical asset.

- Analytics and Insights: Applying AI/ML algorithms to the digital twin enables predictive analytics, anomaly detection, and optimization scenarios.

- Feedback and Control: This closed-loop feedback mechanism allows for real-time adjustments and improvements in the physical system based on insights from the digital twin.

The Actionable Framework: Implementing a Digital Twin for Predictive Maintenance

Here’s a step-by-step approach to implementing a Digital Twin solution specifically for predictive maintenance:

Step 1: Define Your Scope

Begin by pinpointing the specific assets or equipment you want to monitor. Prioritize those with high operational costs, potential for failure, or significant impact on productivity.

Step 2: Sensor Selection and Deployment

Identify the key parameters to be monitored (e.g., temperature, vibration, pressure) and select the appropriate sensors. Ensure the sensor network is robust and capable of providing reliable, real-time data.

Step 3: Data Integration and Platform Setup

Choose a suitable platform for data integration and processing. This could involve cloud-based solutions or on-premise infrastructure, depending on your needs. Establish data pipelines for secure data transmission.

Step 4: Digital Twin Creation

Develop the digital replica, which includes building models of the physical assets. This might involve 3D modeling, physics-based simulations, or a combination of both.

Step 5: Predictive Analytics Integration

Integrate AI/ML algorithms to analyze the data stream and identify patterns, anomalies, and potential failure points. Train your models with historical data.

Step 6: Real-time Monitoring and Alerting

Set up a system for real-time monitoring of key performance indicators (KPIs) and configure alerts to notify maintenance teams of potential issues.

Step 7: Continuous Improvement

Regularly assess the performance of the digital twin and refine the models and algorithms. Embrace iterative development to improve accuracy and predictive power.

Analytical Deep Dive

A recent study revealed that companies using Digital Twins for predictive maintenance experienced a 20% reduction in unplanned downtime and a 15% increase in operational efficiency. This translated into significant cost savings and increased productivity.

Furthermore, the integration of digital twins into supply chain management has led to an average of 10% improvement in inventory optimization and reduced lead times. These results demonstrate the tangible value Digital Twin Technology offers in enhancing operational performance and profitability.

Strategic Alternatives & Adaptations

Digital Twin implementations can be adapted based on user proficiency levels:

- Beginner Implementation: Start with a simple, pre-built digital twin solution for asset monitoring and basic predictive maintenance. Focus on the core data acquisition and visualization aspects.

- Intermediate Optimization: Expand the scope by integrating more complex data sources, incorporating more sophisticated analytics, and experimenting with predictive maintenance models.

- Expert Scaling: Develop a comprehensive digital twin ecosystem that integrates with all aspects of your operations, including supply chain, product design, and customer service. Leverage custom models and advanced analytics for complete system optimization.

Validated Case Studies & Real-World Application

Consider the example of a large aerospace manufacturer. By deploying Digital Twins to monitor jet engines, they were able to predict maintenance needs more accurately. This resulted in reduced aircraft downtime, minimized repair costs, and enhanced flight safety. The ability to simulate real-world scenarios on the digital twin allowed for proactive intervention and optimized maintenance schedules.

Another practical use case includes a leading construction firm using digital twins to optimize the construction of a high-rise building. This allowed them to identify potential bottlenecks in the process, improve resource allocation, and accelerate the project timeline significantly.

Risk Mitigation: Common Errors

Avoid these pitfalls during your Digital Twin implementation:

- Insufficient Data Quality: Ensure your data streams are reliable and accurate. Inaccurate data will undermine the effectiveness of your digital twin.

- Lack of Integration: Ensure seamless integration across all parts of your system.

- Overly Complex Models: Start small and scale as your understanding grows. Avoid building over-complex models from the outset.

- Poor Communication: Promote collaboration across teams. A lack of effective communication can hinder project progress.

Performance Optimization & Best Practices

To maximize the benefits of Digital Twin Technology, follow these best practices:

- Prioritize High-Value Assets: Focus on the assets that have the most significant impact on your business.

- Ensure Data Integrity: Regularly audit your data sources and maintain high standards of data quality.

- Invest in Analytics Expertise: Build a team with data science and AI/ML capabilities.

- Embrace Iterative Development: Continually refine your digital twins.

Scalability & Longevity Strategy

For sustained success with Digital Twin Technology, consider these long-term strategies:

- Standardization: Develop standardized data formats and protocols to facilitate easier integration and expansion.

- Automation: Automate data collection, processing, and analysis.

- Continuous Training: Provide regular training to your team to stay ahead of the curve.

Conclusion

Digital Twin Technology offers enormous potential for transforming industrial and business processes. Implementing this powerful technology successfully requires careful planning, effective execution, and a commitment to continuous improvement. By focusing on data integrity, robust analytics, and strategic integration, businesses can unlock significant value.

Key Takeaways:

- Digital Twins are rapidly transforming industries.

- The technology relies on strong data, integration, and analysis.

- Success demands a strategic approach to implementation and continuous improvement.

- Scalability can be achieved through standardization and automation.

Knowledge Enhancement FAQs

Q: What is the primary difference between a digital twin and a simulation model?

A: Digital twins are dynamic, always updated with real-time data. Simulation models are usually static representations.

Q: How can I begin implementing a digital twin without a large budget?

A: Start with a pilot project focused on a simple asset and utilize cloud-based solutions.

Q: What are the primary industries where digital twins are currently being deployed?

A: Manufacturing, automotive, aerospace, healthcare, and energy sectors are at the forefront of adoption.

Q: What skillsets are most valuable for a digital twin project?

A: Data science, AI/ML, and industrial engineering are crucial skills.

Q: What challenges do businesses face when implementing digital twins?

A: Data quality, integration, and ensuring user buy-in are common obstacles.

Q: Will digital twin technology replace human workers?

A: It is more likely the technology will augment human skills and enable more efficient operations.

Ready to explore the power of Digital Twin Technology further? Investigate our latest resource, which details how businesses are using Industrial IoT and AI to transform their operations!